Building smarter imaging for the world’s toughest environments

Built on physics, powered by AI, and designed for autonomy, Eoptic develops multimodal imaging systems that deliver real-time insight where other sensors can’t—whether in orbit, on the factory floor, or in the field. Founded in 2020, the Rochester, New York–based company has quickly established itself as a leader in mission-critical electro-optical systems that unite optics, modeling, electronics, and intelligent software. Its 25-person team of engineers and scientists designs imaging solutions capable of operating—and making decisions—in environments too complex for traditional sensing technologies.

“Our mission is to integrate multimodal hardware components with purpose-built software to deliver actionable data,” says Pano Spiliotis, Eoptic’s co-founder and CEO. “Everything we do is based on the physics of the problem first.”

Building from the physics up

Eoptic’s engineering process begins with a digital representation of each project—a physics-based model that predicts how a system will behave before it’s ever built.

“When we’re presented with a new project, we start by understanding the high-level requirements and think through different potential solutions,” Spiliotis says. “Our team uses a strategic work methodology that couples fundamental physics with the customer’s specific challenges.”

Because the company is not tied to any particular supplier or component, each system is designed from the ground up.

Pano Spiliotis, Co-Founder & CEO of Eoptic

“We’re not constrained by hardware or suppliers,” Spiliotis says. “Each component is selected specifically for the application.”

The result, he adds, is a design process that naturally integrates optics, electronics, and software from the start—an approach that allows the company to deliver systems that function reliably in demanding environments.

Advancing AI through synthetic modeling

At the heart of Eoptic’s innovation is its use of synthetic data to train AI before physical prototypes exist. Engineers create virtual data sets across multiple spectral bands to model real-world performance and refine algorithms.

“We generate synthetic data so that when the real data comes in, the models already know what they’re looking for,” Spiliotis says. “It saves time and helps us validate designs long before anything is assembled.”

This approach, Spiliotis says, supports what Eoptic describes as “autonomous vision systems”—imaging tools that interpret, rather than simply record, what they see. “Our strategy begins with optical sensing concepts and a basic design,” Spiliotis says. “That then transitions through hardware and software requirements to create a full-featured, robust solution.”

Dedication in the details: An engineer performs precision assembly inside Eoptic’s clean room, ensuring every instrument meets the highest optical and mechanical standards.

Advancing precision in colorimetric imaging: Eoptic’s custom hardware and software enable automated, multi-angle image capture and spectral measurement for detailed surface analysis.

Serving a diverse industry landscape

Eoptic’s physics-driven approach extends across markets where precision and reliability are non-negotiable.

-

Defense and security – Passive optical systems designed for contested environments.

-

Space – Autonomous imaging payloads capable of interpreting satellite behavior in orbit.

-

Industrial metrology – High-speed optical inspection tools that support automation and onshoring.

-

Medical research – Exploratory multispectral imaging with the University of Rochester for drug discovery and disease detection.

-

Electronic assurance – Imaging systems that verify chip and circuit integrity and security.

“We have expertise in harnessing the power of the electromagnetic spectrum to solve difficult problems,” Spiliotis says.

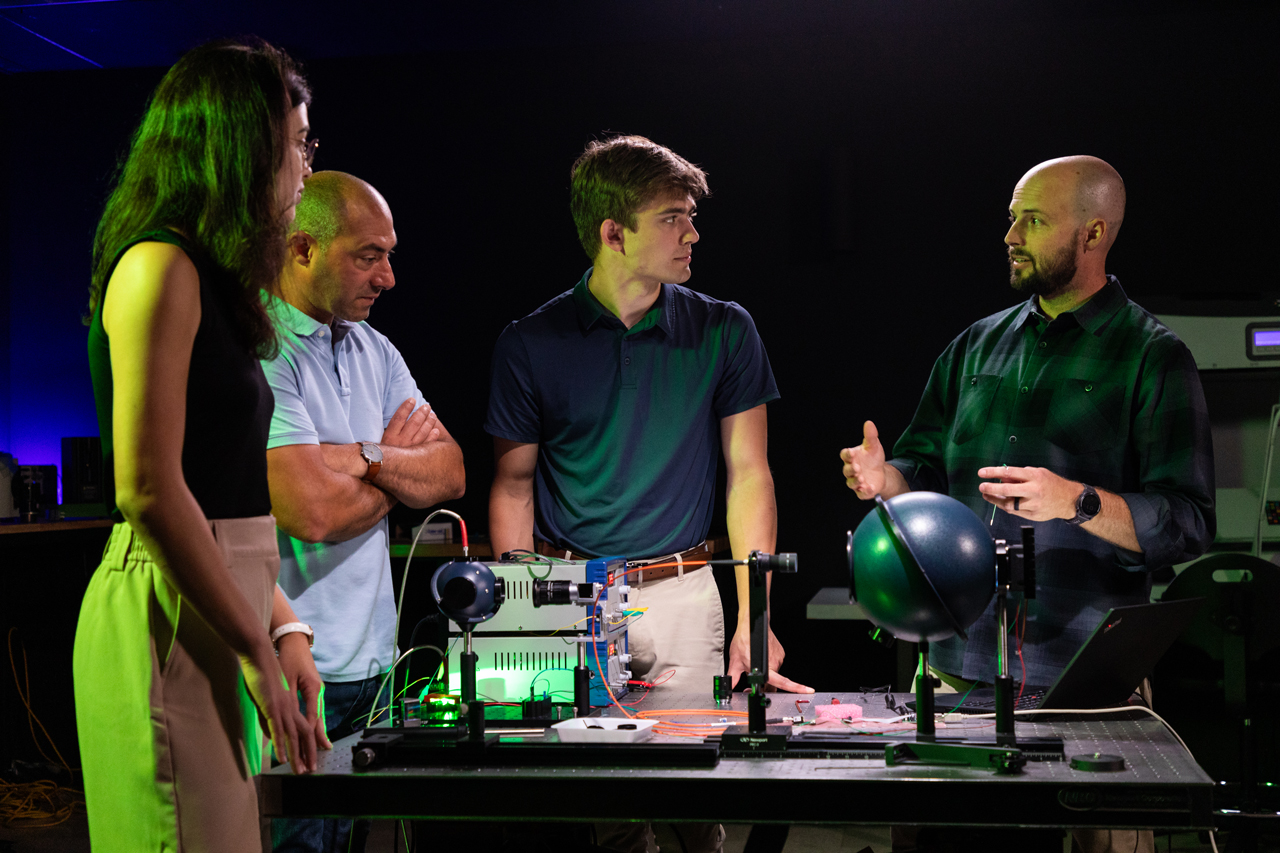

Bridging spectral domains: Eoptic engineers test a next-generation imaging system that fuses visible, SWIR, LWIR, and laser-based sensors – advancing the future of autonomous perception and situational awareness.

Team culture and collaboration

Eoptic’s team combines engineering depth with a collaborative, lab-based environment. Engineers from optics, electronics, and software work closely together to design, test, and refine solutions that bridge the physical and digital worlds.

“Our team is comprised of elite engineers and innovative thinkers with a proven track record of designing, manufacturing, deploying, and supporting optical hardware and software products to solve complex problems,” Spiliotis says.

That mix of expertise, he says, keeps the company focused on careful, purposeful design informed by physics rather than shortcuts or templates.

Bringing ideas to light: Eoptic’s multidisciplinary team explores new frontiers in optical design and imaging technology.

Why DPOC membership matters

As a member of AmeriCOM’s Defense Precision Optics Consortium (DPOC), Eoptic participates in a network focused on advancing U.S. optical manufacturing and workforce development.

“I think it’s important because there’s a scarcity of optical manufacturing,” Spiliotis says. “We have to spread the word—it starts with the young ones looking to get educated, and there’s enormous opportunity here in the United States to build and onshore all these optical imaging systems.”

He says that DPOC provides a platform for collaboration and shared expertise. “It’s about helping the optics industry move forward together,” Spiliotis says.

Interested in joining DPOC? Let’s talk.

The AmeriCOM Defense Precision Optics Consortium (DPOC) is designed to spark new, mission-critical technologies and help the optics industry respond to the needs of the U.S. military. DPOC members have access to AmeriCOM’s COM-Lab, with state-of-the-art equipment to support projects in the precision optics field, including research and proof-of-concept testing.

Membership in DPOC is open to U.S.-based optics manufacturing companies, academic institutions, and other nonprofit organizations. For an overview of member benefits, visit our Manufacturing Technologies page. To join DPOC, submit this Application Form and a member of the AmeriCOM DPOC team will contact you about next steps. Questions? Contact Mike Pomerantz, Director of Engineering.