Optimax Systems is solely focused on making the finest optics in the world. Founded in 1991, the 500 employees of Optimax continue to redefine what is possible, enabling key aerospace & defense, energy, semiconductor, and space exploration programs previously thought impossible. Customer success fueled Optimax’s growth and success.

At its core, Optimax is an engineering company that manufactures optics—constantly seeking solutions that intersect performance, cost, risk, and timeline.

It was pursuit of such a solution that introduced Optimax to the Lawrence Livermore National Laboratory National Ignition Facility (NIF) and the world of pulsed high-energy laser (HEL) applications in 2005. NIF taught Optimax that, for an optic to survive a high-energy laser (HEL) environment, an unbroken chain of events must occur in an exact order with a confirmed outcome. Optimax struggled initially but quickly learned the importance of cleanliness, metrology, and coating. With NIF’s guidance, Optimax gained expertise on how to manufacture pristine surfaces, robustly coated and characterized. Fabrication process introductions like controlled removal led to low-scatter and low-loss surfaces and PET-G containers for packaging ensured cleanliness of the optic, both of which were unheard of at Optimax a year earlier but are now the norm.

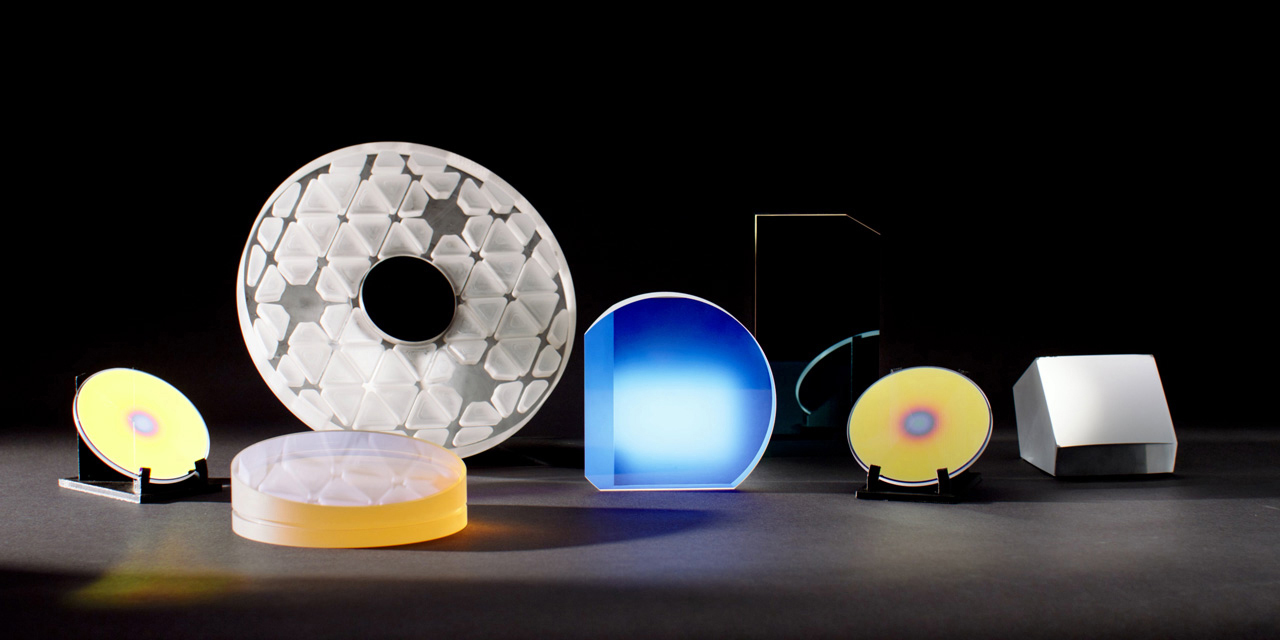

Optics displaying the wide variety of shapes/light weighting features and optical coatings manufactured at Optimax.

View of coating chambers housed within Optimax’s 15,000 sq. ft. environmentally controlled optical coating clean room.

Optimax learned how to diagnose true root cause of laser damage failures—driving toward fundamental understanding of what establishes optical performance and then building a process to guarantee that performance. Understanding led Optimax to design more robust coatings to withstand the laser energy and to seek out suitable metrology. In some instances, the best option was for Optimax to design and build metrology solutions sufficient to validate and ensure HEL-level performance.

This capability became a core competency at Optimax as seen in the final result. Optimax supplied more than 10,000 of NIF’s small optics over 15 years and collaborated with NIF scientists to improve laser damage performance across the entire system.

The main market for this capability was sunsetting (NIF build ended), and Optimax didn’t want to lose it. Optimax went searching, found Directed Energy (DE) that used continuous wave (CW) HEL, and, drawing from what Optimax had learned then built for pulsed, set down the path to bring the same confidence to the CW world. Over the past decade, Optimax has invested significantly in infrastructure, fabrication and coating equipment, metrology solutions, and engineering solutions to prepare capability for the challenges of CW HEL manufacturing in volume.

Investment in advance of demand combined with the execution of Army ManTech programs focusing on large format (up to 500 mm OD) mirror manufacturing, DE coatings, and metrology solutions has allowed Optimax to stand up capabilities and capacity to meet the current need for high performance HEL optics. Established, dedicated manufacturing capacity, proven metrology, and engineering processes specifically geared towards the creation of HEL optics are ready.

View of manufacturing cell for large format optics housed within Optimax’s 230,000 sq. ft. facility.

Manufacturing efforts focused on establishing processes and scalable capacity for large format HEL OAPs/mirrors in an array of materials. Optimax has since leveraged this know-how for all HEL optics, ensuring all HEL optics are manufactured and measured to the same stringent standards.

Optimax coating efforts now focus on establishing robust coatings that withstand the harshness of HEL applications but also deliver exceptional performance. Optimax mitigates risk through modeling and deposition strategies that keep stress low, uniformity high, and resist FOD-induced damage while preserving wavefront. Additionally, established in-house LDT testing, including surface mapping for cosmetic and thermal heating anomaly detection, ensure Optimax HEL optics will not only survive, but perform in any DE system.

These investments have resulted in producing 100s of HEL optics to meet the demands of existing DE programs, allowing Optimax to increase our overall manufacturing readiness. When combined with the dedicated, scalable capacity for both fabrication and coating, Optimax is fully ready, prepared to meet the future demands and requirements for HEL optics.

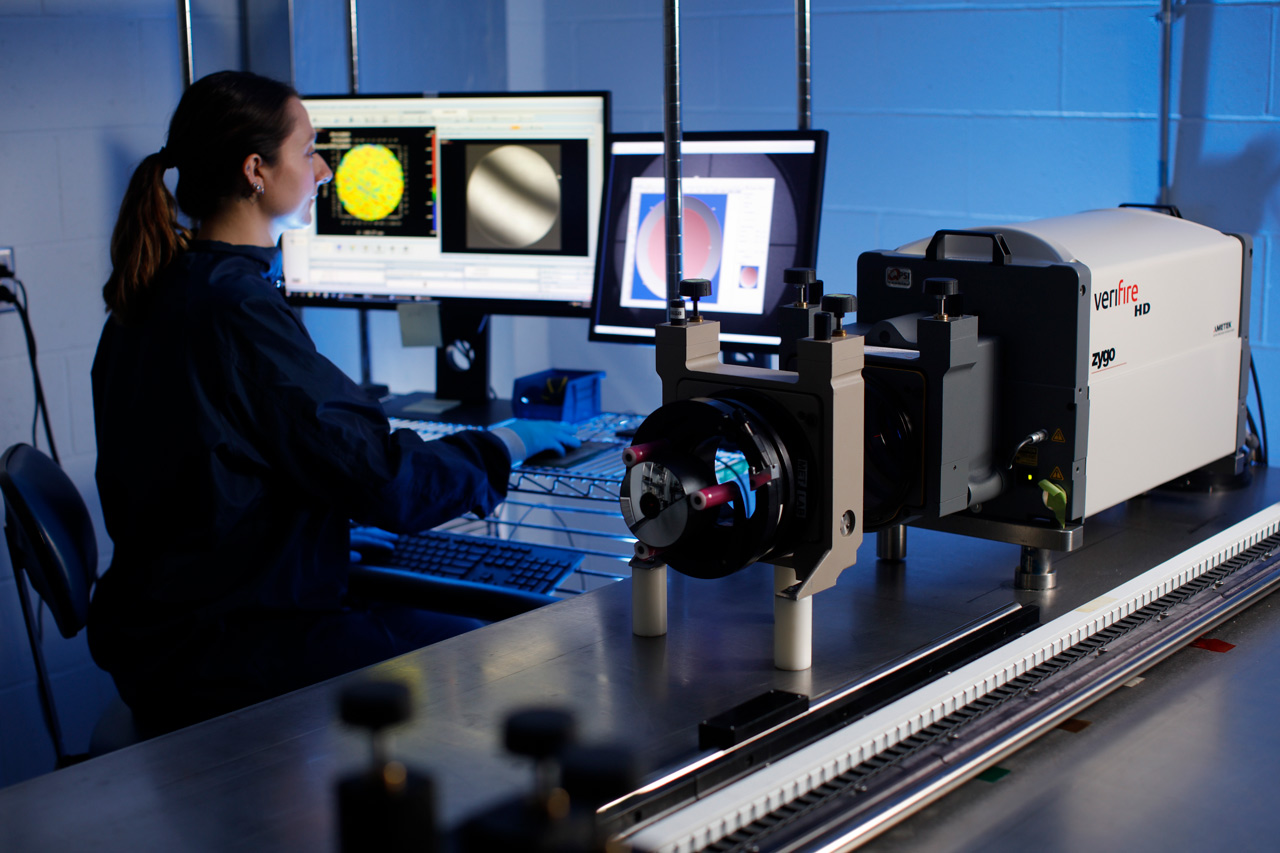

View from within 1 of Optimax’s 6 environmentally controlled optical metrology labs.

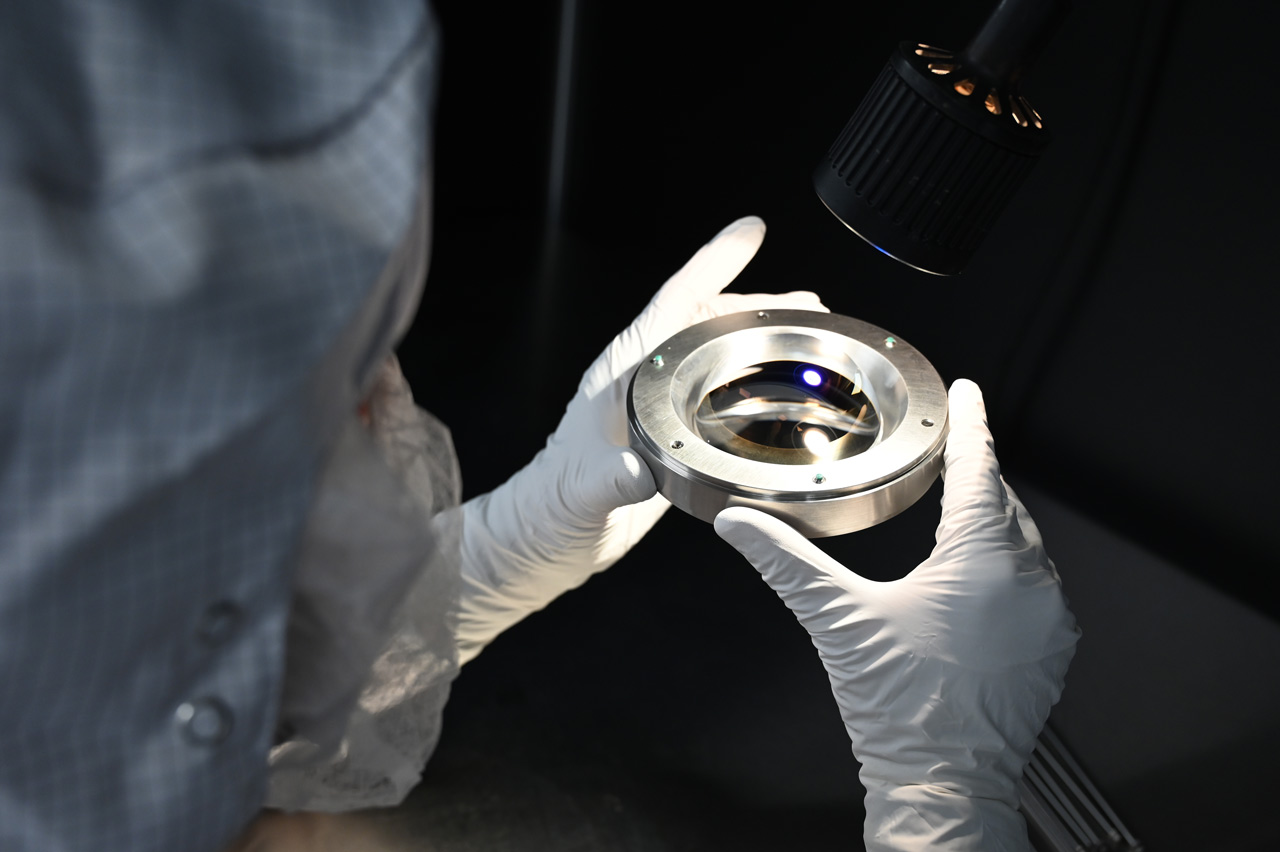

Visual inspection of an optic in Optimax’s packaging clean room.