Written by Bruce Perilloux, BP Scientific LLC

High energy-lasers (HEL) are already demanding on performance requirements of component optics and especially coatings. High CW beam intensities and relatively large spot sizes challenge coatings for lowest intrinsic absorption, fewest nano-scale defects, and stoichiometry consistency. For high reflector (HR) mirror coatings made with multi-layer-dielectric (MLD) coatings, process control, cleanliness of substrates, environment, and coating process itself must be optimized to reduce these defects.

Still, there are always some of these defects that are typically sparse, as well as intrinsic absorption of about 10 PPM or lower. For relatively large spot sizes on HEL optics, there is a need to ensure that testing of representative coatings on witness samples, or actual parts, if possible, is representative of the entire spot area. Optical absorption can be measured via mapping or scanning as has been done in other applications, such as for the interferometer mirror coatings for the LIGO gravitational wave detectors (https://dcc-llo.ligo.org/public/0140/P1700029/005/4869-Billingsley-v5.pdf).

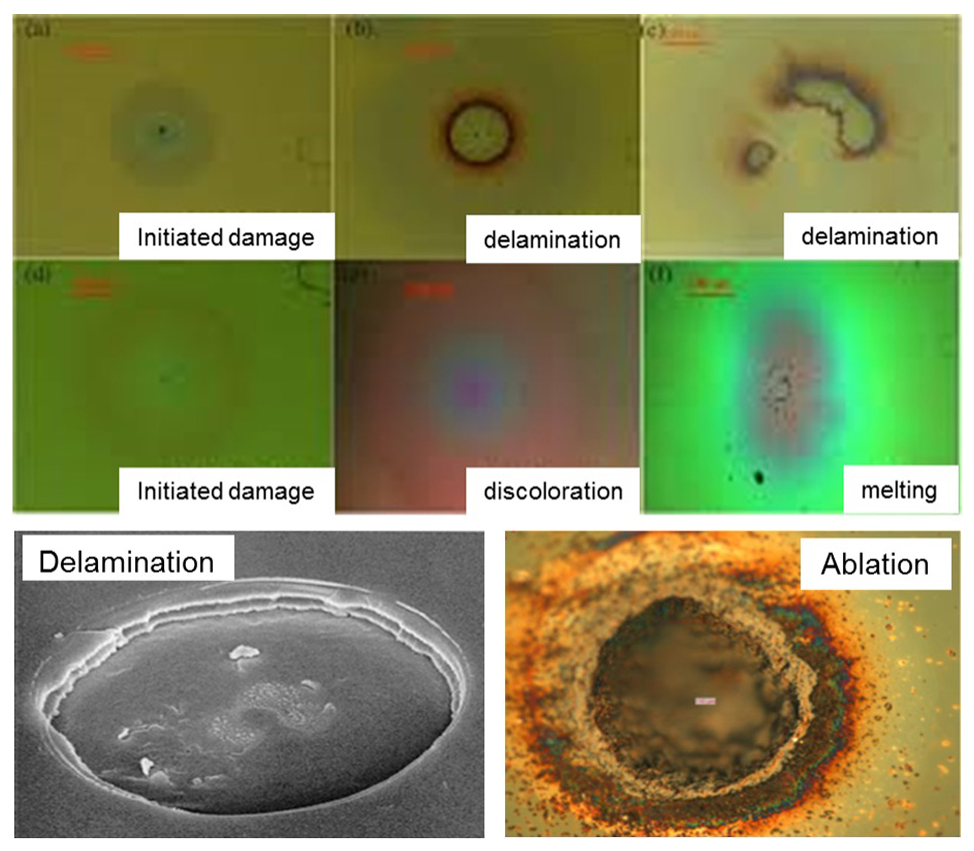

Images at 150X magnification of irreversible changes (damage) induced by laser irradiation. (Images courtesy of Coherent Corp.)

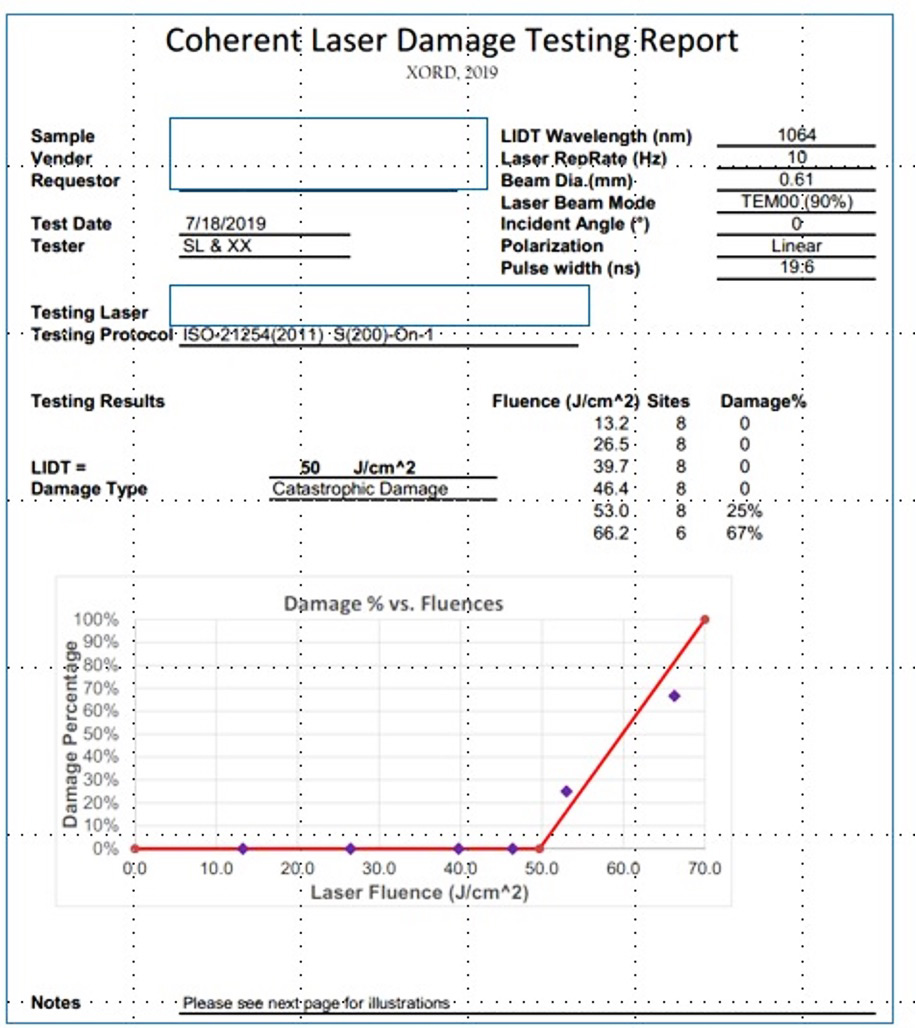

A typical laser damage test report with laser-induced damage threshold (LIDT) value of a sample.

However, this is challenging and not practical for conventional laser-induced damage threshold (LIDT) testing of small spots of about a few hundred micrometer diameters. For HEL optics, much larger areas need to be evaluated, but maximum laser irradiance may limit and not allow testing that causes laser damage or the corresponding laser damage threshold value.

Just the same, for quality control and product verification, LIDT determination or at least certification (pass/fail) are needed that statistically represent HEL coatings over the area that HEL beams will impinge them. This requires a unique specification for LIDT over a large area, and a LIDT measurement method that is better suited for testing larger areas as well as being statistically representative.

To support the HEL optics industry, it would also be helpful if this test method was standardized. This is where the recently released ISO standard 21254-1:2025 provides a solution.

ISO 21254-1:2025 Lasers and laser-related equipment — Test methods for laser-induced damage threshold, Part 1: Definitions and general principles (ISO 21254-1:2025)

The ISO 21254 standard has four parts, where the first is shown above, the second covers threshold determination, the third covers assurance of laser power (energy) handling capabilities, and the fourth is on inspection, detection and measurement. The recently updated Part 1 is technically revised that includes the following:

- new terminology ‘functional damage criteria’ and ‘functional damage threshold’

- two new LIDT test methods:

- Functional R(S)-on-1 test, and

- Functional raster scan test

These two new tests are in addition to the prior 1-on-1, S-on-1, and acceptance tests.

As this updated Part 1 standard states, the Functional raster scan test is recommended for large optics and where the dominant damage mechanism is from defect sites that are sparse. This is important for HEL optics and coatings as these optics/coatings typically have low intrinsic absorption, and sparse defects as stated above. As with all LIDT tests, they are approximations based on several uncertainties, and each has risks that need to be evaluated. Still, the functional raster scan test is appropriate for testing HEL optics for LIDT, and could be done along with the laser damage acceptance test (ISO 21254-3). This new functional raster scan method is potentially beneficial to the optics suppliers for HEL optics.

Laser damage testing is quite involved and even interpretation of results requires some basic understanding of the test method, how damage is detected, and the estimated value of LIDT.

Questions for Bruce? Contact him at bpscientificllc@gmail.com.

This ISO standard for testing laser damage will be reviewed along with dozens of other standardized tests in optics and photonics at Optifab on October 20, 2025. This course was developed under a grant from AmeriCOM to the Optics and Electro-Optics Standards Council, and will be taught by Jennifer LeBaron Michels, Redhead Optical. Learn more here.