Within the scenic Monadnock Region of southern New Hampshire, 603 OPTX is transforming the world of high-precision optics, while investing deeply in the community it calls home.

Founded in 2018 by a team of industry veterans, 603 OPTX was built on a vision: deliver advanced optical solutions with a customer-driven mindset, while fostering a company culture rooted in technical excellence, innovation, and integrity. With over six decades of combined experience, the founders understood that solving complex optical challenges wasn’t just about capability, it was about collaboration and responsiveness to customers.

In 2020, that vision was accelerated when 603 OPTX was acquired by Micro-LAM, Inc., an innovative Michigan-based company known for its technology in precision optics manufacturing rooted in the Optimus Laser Assisted Machining system and a shared belief in pushing the boundaries of what’s possible in optics fabrication. Today, 603 OPTX is recognized as one of the world’s most advanced precision optics manufacturers serving defense, scientific, medical, industrial, and space-based markets with high-performance components built for demanding environments.

Why 603 OPTX joined DPOC

As part of its continued evolution, 603 OPTX recently joined the Defense Precision Optics Consortium (DPOC). The company sees DPOC membership as a platform to expand visibility, contribute to technical working groups, and build relationships that drive innovation across the defense optics landscape.

“Joining DPOC strengthens our ability to collaborate with leading defense contractors, fellow optics manufacturers, and U.S. government stakeholders,” says Matt Zabko, General Manager of 603 OPTX.

“It also reinforces our commitment to growing domestic capability in strategic materials like germanium and scaling production capacity to meet evolving national security needs.”

Stephen Polczwartek and Matt Zabko are all smiles as 603 OPTX receives two new Nanotech 250UPL machines in early 2025.

One of the four production bays at 603 OPTX.

Investing in technology and talent

From its 8,000-square-foot, temperature-controlled facility in Keene, 603 OPTX runs a full spectrum of optical manufacturing processes. With an ever-growing team including engineers, technicians, operators, and support staff, the company brings together a powerful mix of technical expertise and innovative problem-solving.

The company fabricates everything from metal mirrors to complex lenses including off-axis aspheres, freeforms, and diffraction-based elements. And 603 OPTX works with a wide range of materials that reflect the company’s versatility, from aluminum to NiP-coated substrates to glass to specialty alloys like Invar to infrared crystals like germanium.

603 OPTX has a deep bench of metrology tools to ensure tight tolerances and reliable performance, such as a Taylor Hobson Luphoscan 360 HD, Zygo Verifire interferometers (4″ and 6″), PGI profilometry, CMMs, among others. The team can also meet demands on many scales, from prototyping and to high-volume production, thanks to a fleet of eleven 2-, 3-, and 5-axis diamond turning platforms from local partners Moore Nanotechnology and Ametek Precitech.

603 OPTX invests heavily in state-of-the art metrology equipment. Here Technician Nate Greci measures an optic on the Taylor Hobson Luphoscan 260 HD.

A commitment to Keene

While the company’s capabilities are vast, one of its most important investments is in people, including the larger community. That commitment has shaped the company’s strong and growing relationship with Keene State College (KSC), just a few miles from 603 OPTX.

KSC’s optics and physics programs serve as a talent pipeline, and 603 OPTX has leaned into the opportunity. The company works closely with KSC to offer internships, facility tours, and mentoring relationships that give students real exposure to industry challenges and processes. Interns take part in real, hands-on projects, collaborate with experienced technicians, and often move into full-time roles after graduation.

One standout success story is Sam Cloutier, a KSC graduate who began as an intern and now serves as a full-time employee. His journey reflects the broader goal: create pathways for local students to develop high-impact careers in optics and precision manufacturing, right here in New Hampshire.

603 OPTX regularly hosts KSC optics students for internships, on-site visits and facility walkthroughs, helping them see firsthand what it takes to manufacture mission-critical optical components. These sessions are designed not just to inform, but to inspire—exposing young professionals to advanced technology, applied science, and the meaningful role optics play in everything from medical diagnostics to space-based communications.

Sam Cloutier, a KSC alum who began as an intern and now serves as a full-time employee.

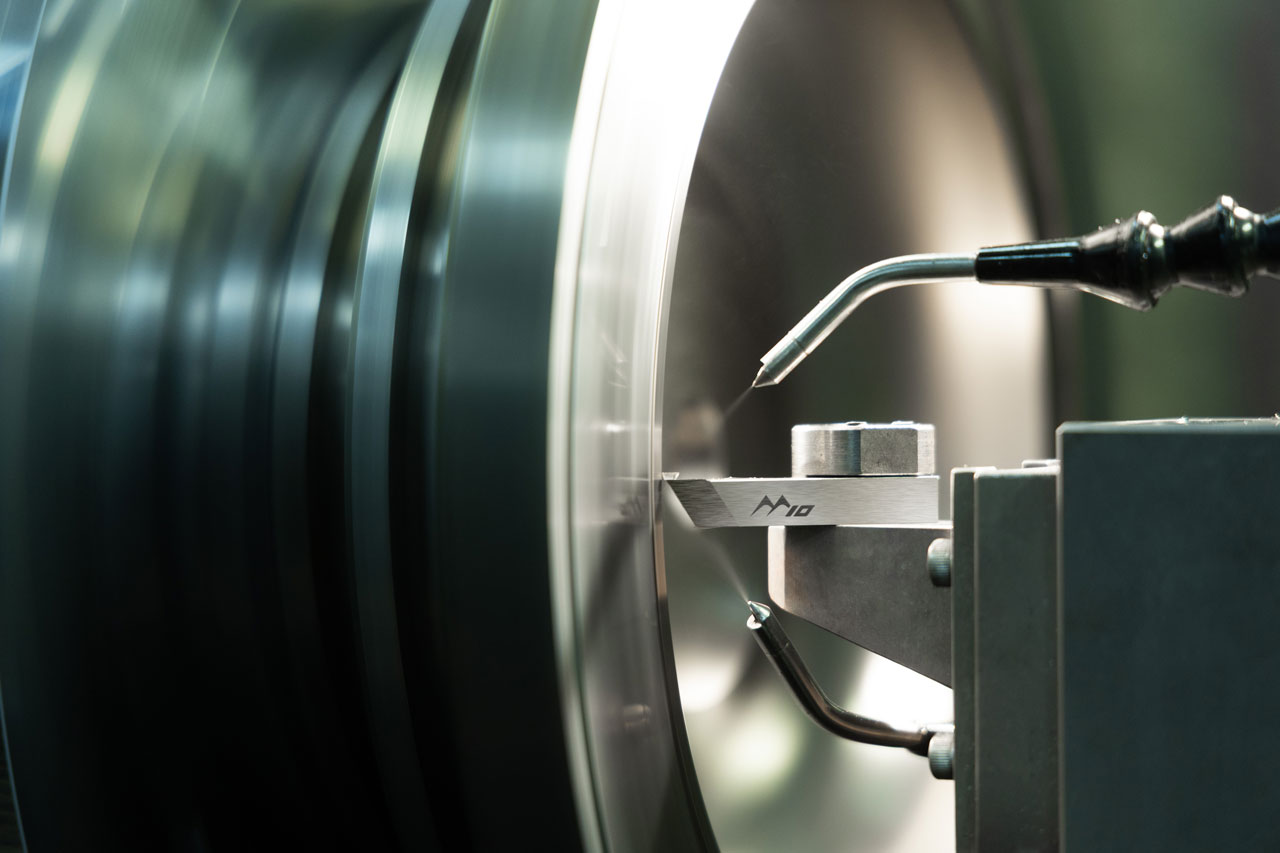

Taking advantage of the vertical integration form being a Micro-LAM, 603 utilizes M10 edge diamond tools. Another Mirco-LAM brand.

Silicon lenses machined with the Micro-LAM Optimus system make their way through production.

Looking ahead

While the 603 OPTX team is growing, its values remain the same. Solve problems for clients. Be responsive. Be bold and forward-thinking. Embrace diversity. Operate with integrity. And the road ahead includes new markets, new talent, and new challenges as well as new opportunities to strengthen both the optical industry and the Keene community. Because 603 OPTX isn’t just building optics. They’re building a legacy—one innovation and one person at a time.

Interested in joining DPOC? Let’s talk.

The AmeriCOM Defense Precision Optics Consortium (DPOC) is designed to spark new, mission-critical technologies and help the optics industry respond to the needs of the U.S. military. DPOC members have access to AmeriCOM’s COM-Lab, with state-of-the-art equipment to support projects in the precision optics field, including research and proof-of-concept testing.

Membership in DPOC is open to U.S.-based optics manufacturing companies, academic institutions, and other nonprofit organizations. For an overview of member benefits, visit our Manufacturing Technologies page. To join DPOC, submit this Application Form and a member of the AmeriCOM DPOC team will contact you about next steps. Questions? Contact Mike Pomerantz, Director of Engineering.