The U.S. germanium supply chain is under threat facing shortages and rising prices. It is well known that China currently has a major advantage in the production of germanium; however the problem is not a disparity of geographically available material, but rather a lack of metallurgical processing in North America. Such processing formerly existed in the U.S. but was driven offshore by Chinese and other foreign-backed firms that were able to operate at a loss for years. In 2023 and 2024, China implemented export controls and an export ban on germanium to the U.S. causing shortages, rising prices, and an urgent need for new supplies.

Germanium is a silvery-white metalloid primarily used in infrared optics, fiber optics, solar cells, and electronics. Germanium’s advantageous optical properties such as high index of refraction and transparency through the long-wave infrared band make it the material of choice for many military night vision and infrared systems. Solar cells made with germanium are about three times more efficient than solar cells made with silicon, and therefore are heavily used for power generation on satellites and other space-based platforms. Modern technology depends on a reliable supply of this critical mineral, and demand is forecasted to increase both for defense and commercial uses. While historically, the U.S. has used approximately $40 million worth of germanium per year, a recent USGS report estimates the Chinese export ban will result in a $0.4 to $1.1 billion decrease in GDP due to supply disruptions. If germanium is critical for defense needs, how did the U.S. end up in the situation where a foreign power is able to control access especially when germanium can be found within the continental U.S.?

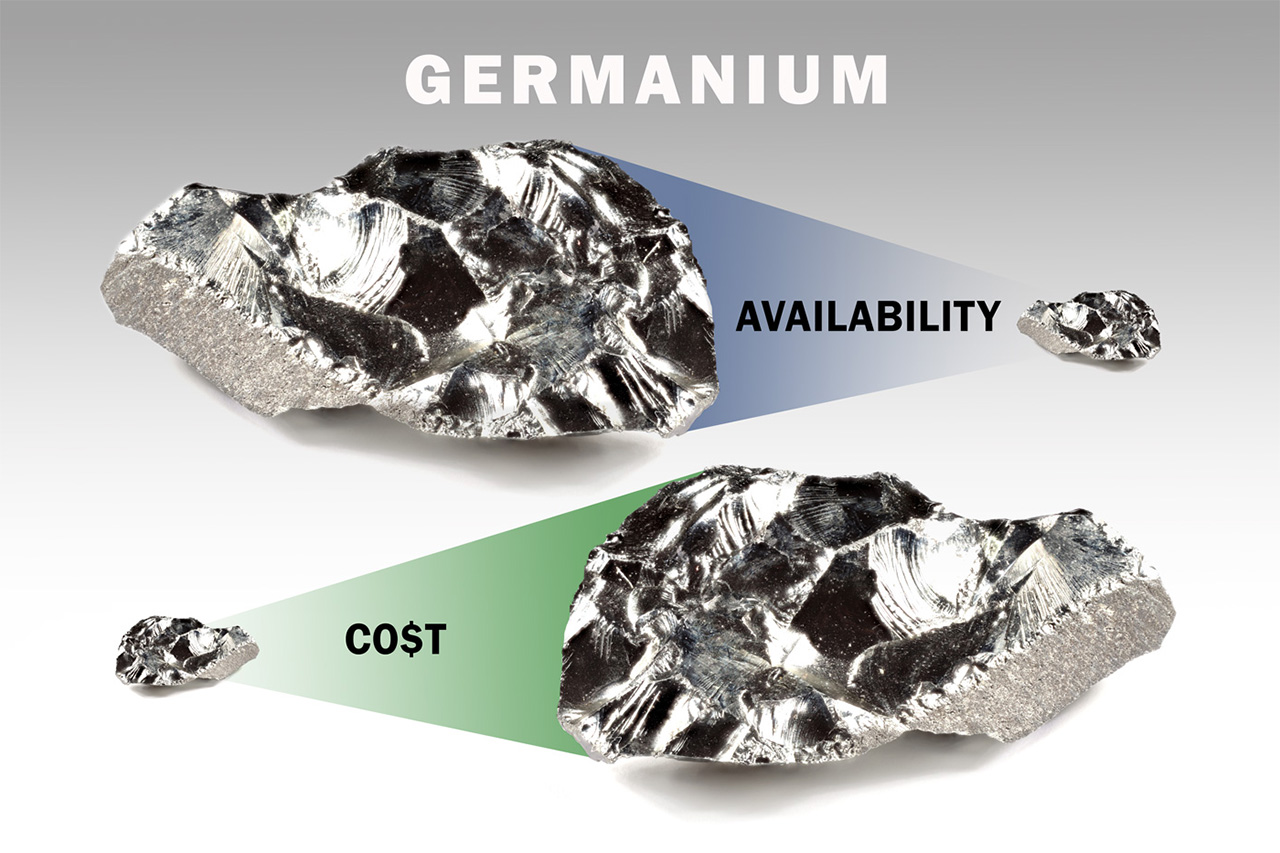

Germanium is typically extracted as a byproduct of zinc mining or from burning coal. The material undergoes processing and refinement until single crystal boules of germanium are grown and sliced into wafers and optical blanks. Historically, the entire process could be performed within the U.S., but the subsidized germanium industry in China and elsewhere meant that finished germanium products could be purchased overseas at a lower cost than the cost to produce the raw material, driving U.S. companies out of business. Alternative materials and advanced optical system designs can help reduce the amount of germanium used, but there is no drop-in replacement for germanium optics and no alternative for space based solar cells. To secure the U.S. supply chain, a domestic source of germanium from dirt to refined ingot must be established and protected from foreign price manipulation.

The biggest challenge facing the domestic germanium industry is not geological availability or a technical challenge but rather the financial risk associated with standing up domestic supply and processing. An AmeriCOM developed rough order of magnitude cost model predicts that the entire U.S. need of germanium could be satisfied with a $200 million investment that would be profitable within 3 years and with a return on investment of about 80% over 6 years. This cost model assumes that the price of germanium stays stable, however, China is sitting on a stockpile of material and there is nothing preventing them from flooding the market to drive down prices. In fact, this happened previously in 2003 and again in 2016. Until the domestic supply chain can be insulated from foreign price manipulation, private investment into germanium will be deemed too risky.

The U.S. Government is becoming aware of the problem with germanium and other critical minerals, and there are some programs and funding to try to alleviate the supply shortage. The DLA has established a recycling program to reuse germanium from decommissioned military equipment. DOE has provided funding to set up pilot plants for extracting rare earth minerals including germanium. The Army is supporting SBIR contracts to extract germanium from waste coal ash deposits. DPA Title III funds have gone to support germanium wafer production. Executive Order 14241 from March 20, 2025 authorizes the Secretary of Defense to facilitate private capital with commercially viable domestic mineral production projects to the maximum possible extent and adds mineral production as a priority industrial capability development area for the Industrial Base Analysis and Sustainment Program. To reduce the financial risk, the U.S. germanium industry would benefit from minimum price guarantees, chain of custody requirements, and requirements to buy a certain percentage of germanium from American sources in Government procurement contracts. In the meantime, germanium prices will remain high and supply short while supply chains are transitioned away from China.

AmeriCOM is addressing germanium supply chain challenges through a variety of actions. AmeriCOM has published a cost model and report for Government stakeholders on germanium extraction and refinement as well as suggestions for further actions. AmeriCOM has held several meetings at Congressional Offices to inform and educate leaders on the importance of germanium to the defense industry and current market challenges. AmeriCOM has hosted webinars, given interviews for critical minerals roundtable discussions, administered surveys, and recently helped host a germanium technical exchange event at Ft. Belvoir. We look forward to continuing to advocate for the defense precision optics industry.

Bold ideas, real talk: Germanium takes center stage at Virginia conference

AmeriCOM recently helped host a germanium technical exchange with Army C5ISR at Ft. Belvoir, Virginia. Nearly 150 people from Government and the germanium industry including mining, refining, crystal growth, component production, and the prime defense contractors were in attendance. The purpose of the event was to bring together stakeholders across the germanium supply chain to address current global trade barriers and market challenges that will inform U.S. Government policy through insights gathered from the participants. The morning of the event consisted of presentations from Government stakeholders such as the Defense Logistics Agency, Department of Energy, Army C5ISR, and Space Force. These presentations outlined the importance of germanium to national security, the current and growing need for a stable supply of germanium, and government programs to support domestic germanium production and recycling. The afternoon of the event comprised of four industry panel discussions focused at each level of the germanium supply chain including mining and refining, crystal growth, component fabrication, and system integration.

Feedback from the event has been very positive and we are optimistic that there are numerous short- and long-term solutions that collectively will solve the germanium supply chain crisis. AmeriCOM would like to thank Army C5ISR, especially John Hall for organizing the event, the panel participants, and all the attendees that completed the industry survey.