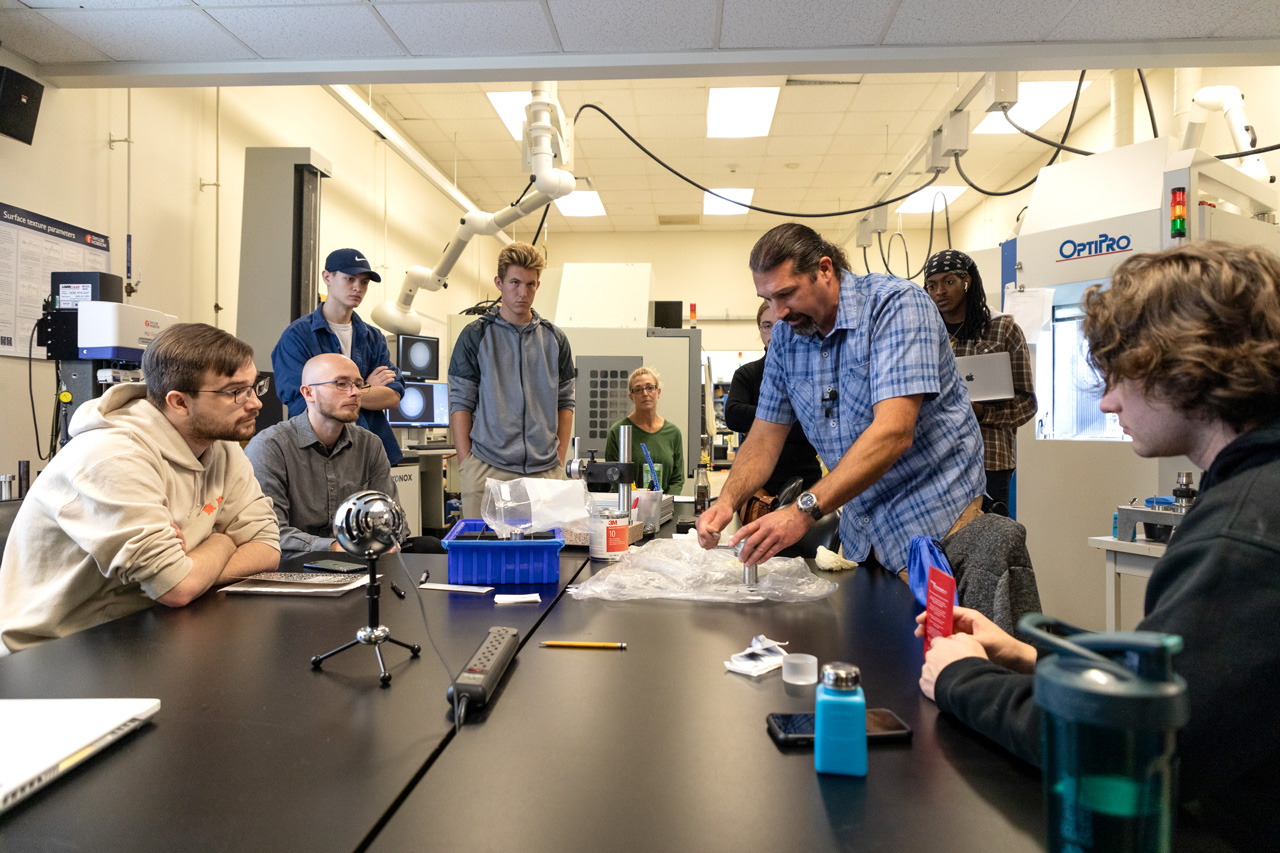

Mike Pomerantz: In the MCC optical lab (above) and teaching students on optics fabrication equipment in the lab. (below).

When did the field of optics first grab your attention?

I wanted to become a machinist and process engineer. After an internship in high school at a local metal shop, my teacher pointed me toward a job at Optimax. They needed a CNC machinist. That was the beginning. Interestingly, I didn’t even know optics was a career option—especially optics fabrication—until I saw it first-hand. Optimax wasn’t machining things out of metal, but out of glass.

What surprised and interested you most about the field?

The artisan nature of the industry. Using hands and machines together to shape cold glass into precise optics. The metrology was most interesting, using light to measure optics.

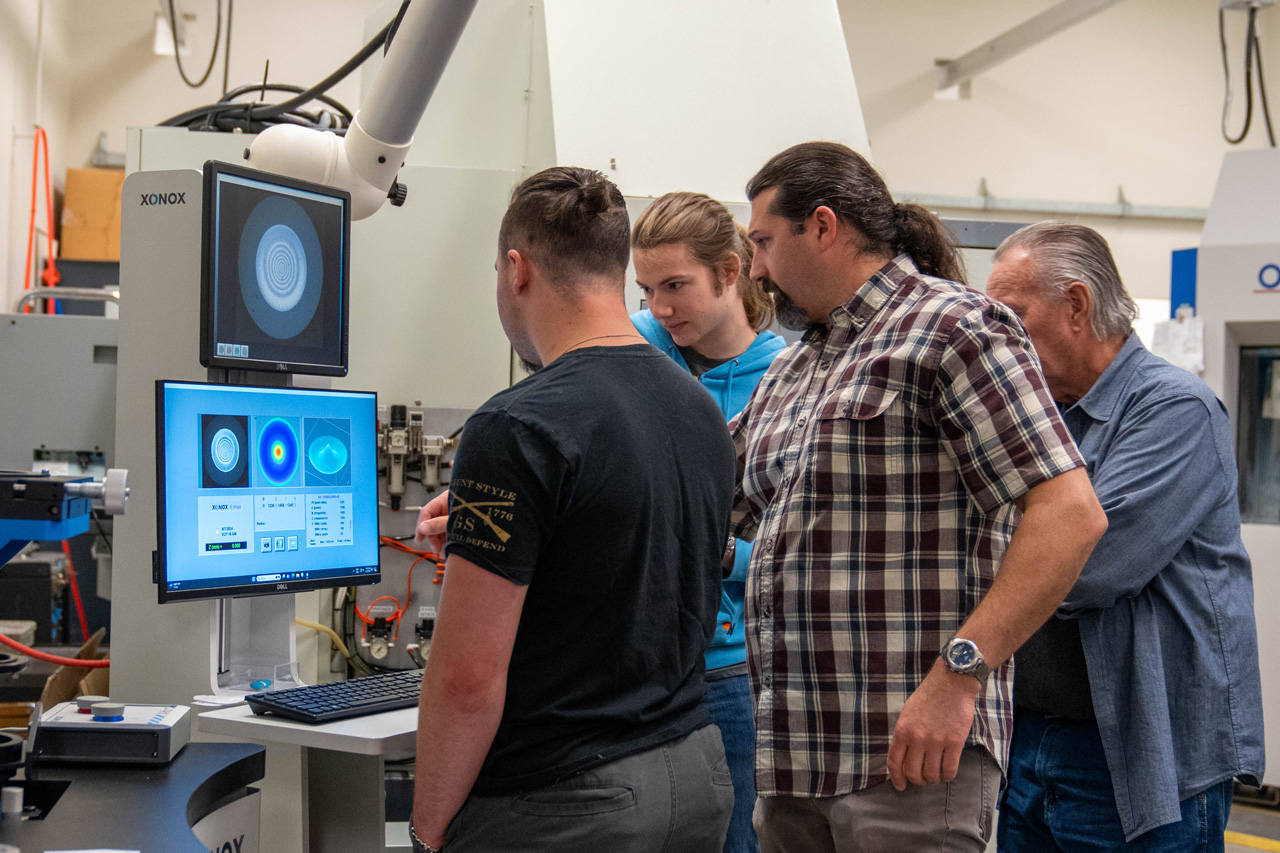

Mike Pomerantz: In the MCC optical lab (above) and teaching students on optics fabrication equipment in the lab. (below).

What do you wish everyday people understood better about optics?

The variety of career paths that there are in optics. My experience has been fabrication. Other experiences could be sales or making the machinery or writing the software or selling the consumable materials or metal housings optics go into. Applications. Research. There are tons and tons of opportunities out there.

Did your parents being teachers influence your path?

Yes, very much. Both of my parents were educators—my dad taught electronics at Wayne Tech and Career Center and my mom taught special education and GED courses.

How do you balance your roles as both a technician and an educator?

It’s a daily balance and it changes every semester. I always aim for a 50/50 split between teaching and technician work.

What does your typical work week look like?

It really depends on the time of year. Spring is always busier because of senior design projects at the University of Rochester. Generally, my week is a mix of hands-on lab work and classroom instruction.

Mike teaching students in the optics technology lab.

In the lab, students receive hands-on training in optics grinding and polishing, single point diamond turning, and more.

How do you introduce optics to your students?

I start by having them think about the tech they already use—VR headsets, phone cameras, Ring doorbells, barcode scanners. When they realize optics are behind all of those, the light bulb goes on. I don’t think they know what to expect other than the promise of a career. Some of them have jobs but it’s just a paycheck. They don’t have any loyalty to the job because it’s not something they want to do for the rest of their life. Finding something where they can use their natural abilities and combine that with an education as a skilled technician. Then growing their career with their two-year certificate or pursuing more education in the field. At MCC, we’ve seen students get to the end of their program and they decide they want to go on and get their master’s. But they wouldn’t have made that decision three semesters prior. They would have laughed in your face.

What excites your students about the field?

The potential for a real career—not just a paycheck. Optics offers them a path to stability: a job, a house, a family, even retirement.

What does it mean to you to give back to the profession?

I was lucky to be trained by incredibly skilled technicians and engineers. I want that knowledge to continue. I want to send well-prepared students into local companies so they can thrive—and so our local optics industry can grow. The fun part is, sometimes I see some of my past MCC students turn up as PhD candidates at U of R. We have a few of those who are progressing to graduate level work. Overall, there’s an amazing concentration of optics businesses here in Rochester. It’s a win for everyone.

What’s your proudest professional accomplishment?

Working on the Mars Rovers—Spirit and Opportunity.

Where do you see the field of optics in the next three years?

We’re going to see more widespread use of meta-surfaces and freeform optics in design. Just like aspheres changed the game 25 years ago, these new surface shapes are the next leap. Over the next 10 years, I expect we’ll see even more innovation—new materials, miniaturization, AI-driven design, and additive manufacturing.

What advice would you give other professionals thinking of becoming instructors?

You need to be able to relate to people who might not have a college background. Be patient. Be creative. Not everything needs to be a lecture.

Mike is one of many industry professionals that teach in the Optics Systems Technology program at MCC.

What’s the story behind your nickname, “PomPom”?

It goes back to fourth grade—my gym teacher started calling me that, and it stuck. Later, my high school soccer coach used it too. When I started at Optimax, there were six Mikes on the floor, so my manager needed a nickname for me. PomPom came back. And it stuck. It’s also grown in the classroom and at trade shows.

What do you enjoy outside of work?

Being outdoors—camping, kayaking, hiking, hunting—or just tinkering in the garage. I also love cooking.

How would your friends describe you?

Hopefully as loyal, helpful, grateful, and talented.

Are you a military veteran?

No, I’m not. But I’m grateful that some of the work I’ve done in optics has contributed to protecting service members and advancing national defense.